[ soundtrack : Scarlatti - Sonata in A Major, K.208: I. Adagio e cantabile - Wolfram Schmitt-Leonardy (piano) ]

***

This post is too long for email — open in browser for full length.

***

This winter, I have been ‘investigating’ stropping, i.e. mucking about with bits of leather glued to blocks of wood. I started out making some stropping blocks in the beginning of December that were part of my Christmas presents for the boys. Since then I have been playing around with an old Arkansas stone and Veritas’ honing compound. I’ve also bought a trio of honing waxes from MPOWER for doing further experiments ...

… but first I must make more honing / stropping blocks. They’re just pieces of leather glued to good-quality plywood, so easily done. On the last batch I used epoxy to glue the leather to the wood, but this time I would use up the rest of my little bottle of Old Brown Glue — hide glue for gluing hide … eh? … eh? (Cheers, Chessick!)

I heated the glue by letting the bottle float in a bucket of very warm water.

While it heated up I cut the leather to (over-)size and sanded the glue-side to roughen it up a bit. Then I vacuumed up the leather-dust — a first for me.

Applying glue and clamping up is easily done.

Nice, thick cauls to help spread the clamping forces:

This time I made a batch of six, using two different kinds of leather.

When the glue had cured I could trim off the excess leather.

I made the blocks as big as my scraps of leather would afford.

When I began applying the MPOWER (what a cheesy name!) honing compound I immediately discovered that it was much ‘drier’ than the Veritas wax I’d tried previously. It was much more chalk-like and did not want to adhere to the leather in the suitably sticky, waxy way that the green Veritas compound did.

Some of it stuck, but I suspect half of it fell off like dust — not very economical. This was the same for all three ‘sticks’. My impression is that the wax did not embed itself properly into the leather surface.

I assume one could improve the sticktivity with judicious use of a heat gun, but wouldn’t it be better if MPOWER formulated their compounds so that you didn’t need an electric tool in order to apply the stuff properly?

This is more of a disappointed quibble than a serious complaint, but still …

I now have many honing blocks to try out, but what toy should I play with?

I chose one of my chisels from MHG; it’s part of a set of cheap, workaday chisels with very comfortably shaped ash handles. The steel is good enough, if not very accurately ground from the factory — but as so often; you get what you pay for and I’ve seen much, much worse.

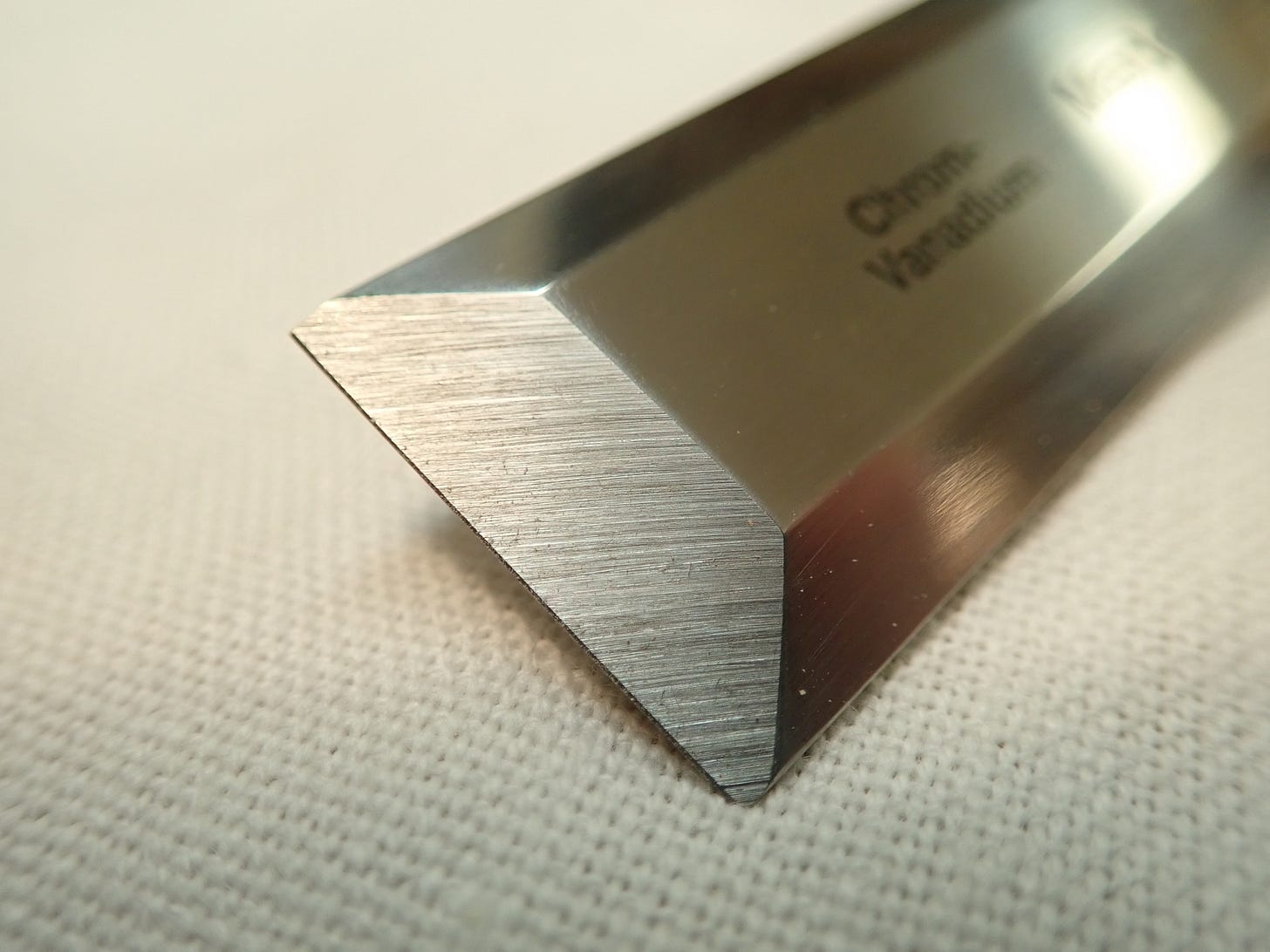

I chose a somewhat oddly sized chisel that I had not previously ‘conditioned’ (put into use):

The back of the chisel reveals the usual ‘sweeping’ toolmarks (face mill?) you expect to find on budget tools.

The thing is: I’ll give the back of the chisel an initial flattening, but all chisels end up with mirror-polished backs in the end, because you hone both sides of it each time you sharpen it (right?), so it’s only a question of time :-)

Aaaach … booooring! This is good enough to go on with.

Then I measured the factory primary bevel with a small, brass gauge.

25º — not unusual. I squared that factory grind off with my own grits-on-glass before I gave it a 30º secondary bevel …

… using finer grits, finishing up on 15µ / P 1.200

This would be the starting point for my stropping experiments.

When stropping on leather you can not move the chisel back and forth, nor sideways; you must pull it edge trailing, lest you mess up the soft leather. If you’re not familiar with the operation, here’s a short video of Paul Sellers doing a brisk demonstration:

Now, I’m not at all used to stropping and have difficulty maintaining the desired honing angle when working freehand like this. I manage much better on oilstones, but then I use another technique (more about this in a later post). Also, I suspect the Old Guard who routinely stropped their tools were less fussed about keeping exact cutting angles like we can achieve today with our fancy honing guides. I’ve noticed that old-school, vintage tool edges (those that have not been grossly mistreated by some ‘enthusiast’) sometimes have a rounded over profile — a convex or ’elliptic’ primary bevel curving down to a polished edge — instead of the precise and distinct bevels we often see today.

As for my stropping experiment, I managed to get a decently sharp edge with a small micro-bevel up front.

I tested it by feeling its sharpness with my fingertips and by hacking at a piece of spruce. You might think that testing sharpness on a very soft wood like this would be cheating, but you’d be wrong. The soft wood will easily and visibly crush if it’s not cleanly cut — it’s a good wood to gauge a cutting edge.

Conclusion: The MPOWER honing wax sticks were a bit of a disappointment. Their dry, chalky composition was unhelpful. They do work, after a fashion, but do nothing my green Veritas compound does not already do better.

Caveat: Since I have very little experience with stropping, I do not know what I’m talking about (there is such comfort in numbers). Furthermore, this is the first time I try this specific product; I will learn to use it better as I persevere.

I’ll keep my new stropping equipment in a drawer close to the bench so that I can easily take it out when my chisels need a touch-up. I’ll keep you posted.

***

I'd suggest trying jeweler's rouge. I use it after green honing compound and it works a treat

Thanks for the shout-out!