[ soundtrack : Ēriks Ešenvalds - O Salutaris Hostia - The Choir of Trinity College Cambridge ]

***

Stropping has never been part of my sharpening regime. I started out on bench grinder & oilstones, honing on a translucent Arkansas stone. Then I dabbled with diamond stones for a while. These last four years or so I’ve used self-adhesive abrasives on glass. In short: I’m a honing whore — I’ll go with any grit that grinds my bevel. Well hello there, sailor!

While I am nicely set up with my ‘grits-on-glass’ honing bench, I’ve been giving some thought lately to my brethren who are working ut’a hus and how they might achieve a good, working edge on site.

Without going into the pros & cons of each and every sharpening/honing system, we might perhaps agree that honing on a building site is a toss-up between oil-stones and diamonds — if any honing is done at all. No one is stopping you from bringing your Japanese waterstones, but could you withstand the merciless ridicule? “Guys! Has anyone seen my Nagura stone?“

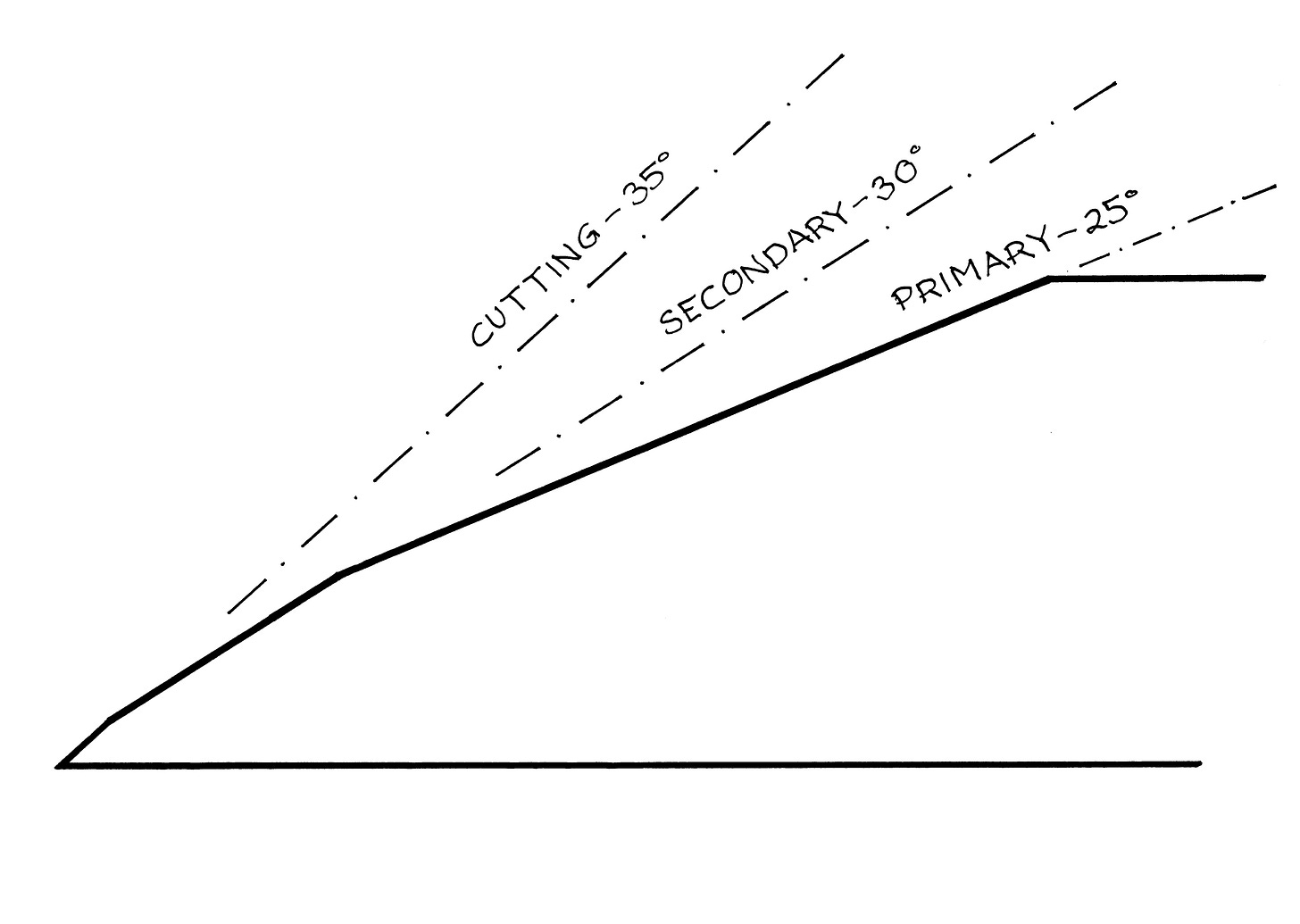

Sharpening on-site has to be practical and unfussy. These are busy, no-nonsense men; they have no time for faffing and fiddling. The problem is that neither oil stones or diamond plates come in sufficiently fine grits for proper honing (the exception being fine Arkansas stones). Hence the stropping idea.

As mentioned, I have almost no experience with stropping. I have a stick of Veritas honing compound that I’ve rubbed on an old bit of leather and messed about with, but other than that I’m blank. I might be an ugly old dog, but I’ll be damned if I’m past learning new tricks, so I’ve concocted a little Christmas-project that involves leather-clad ‘stropping blocks’. This is how I made them.

As luck would have it, we have a leather-shop just up the street (not that kind!) I was allowed a dive in the leftover bin and selected a thin, white skin (title of Dr. DiAngelo’s next treatise?) that seemed to be smooth and homogeneous. I know nothing about leather and making strops, but I had a hunch that since leather is soft, it would be best if it was quite thin so as not to have too much ‘give’ and thus limiting any rounding over of the steel’s cutting edge.

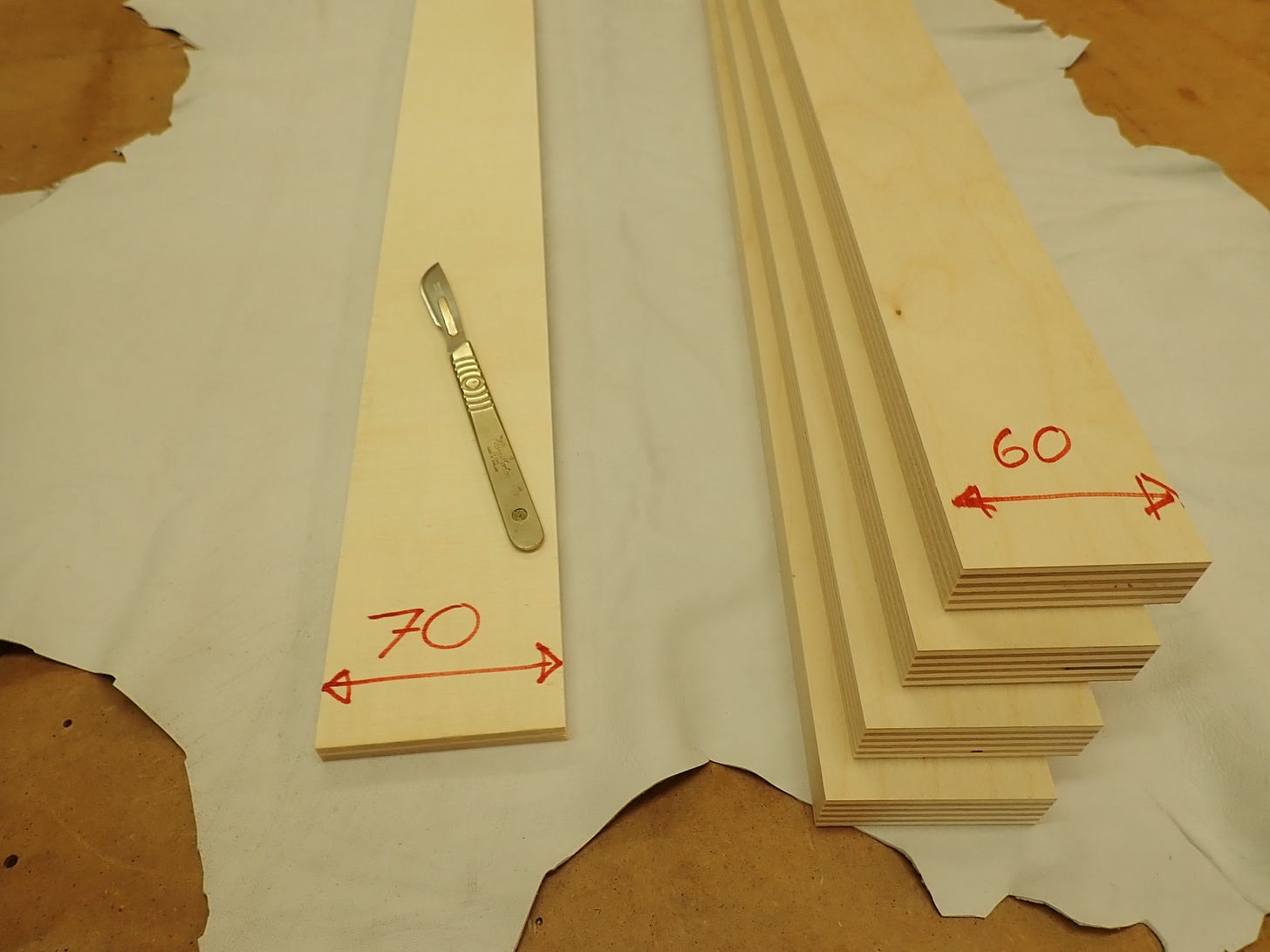

When back home I dug out an old scrap of 18mm birch plywood that I ripped into 60mm wide strips.

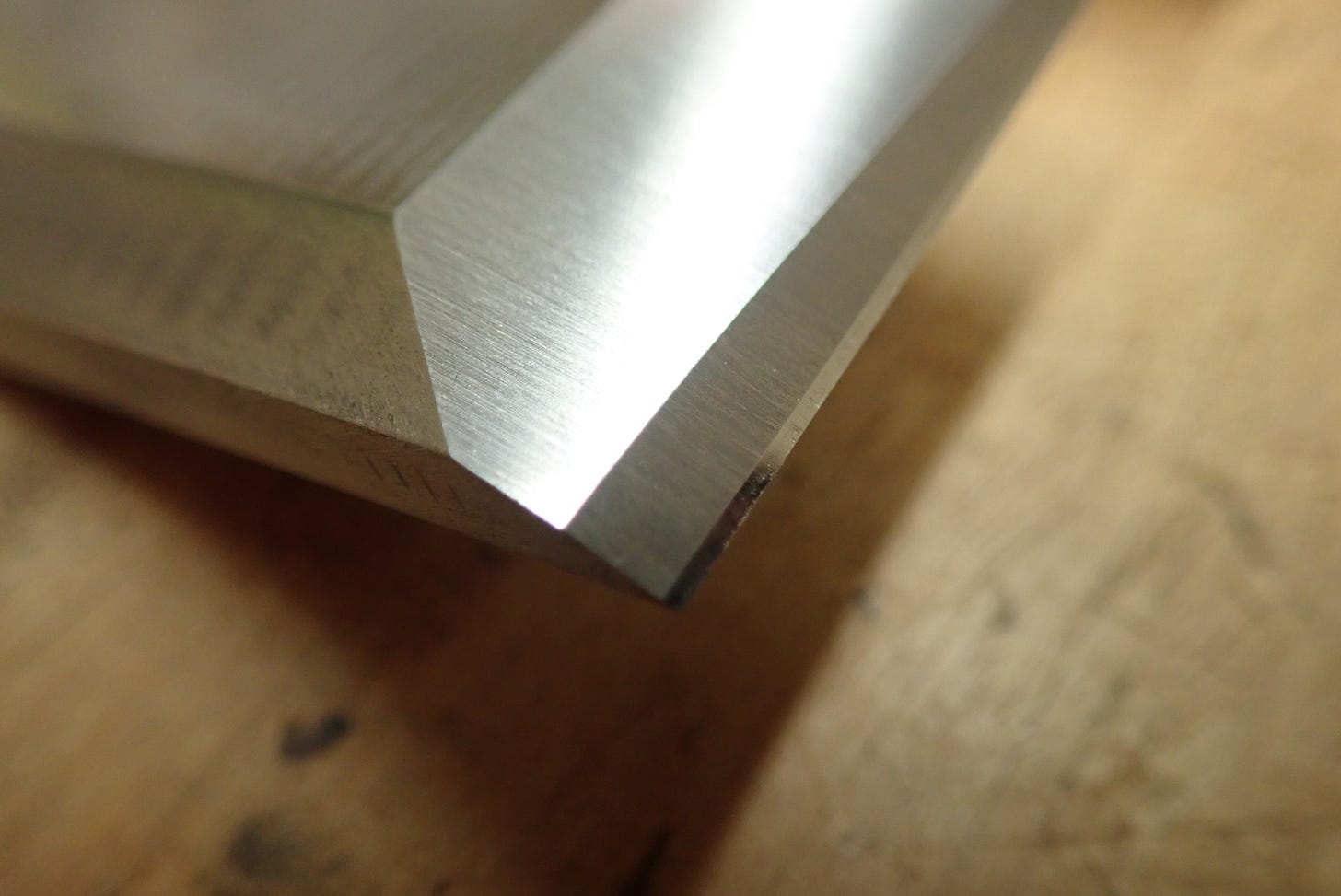

I made a cutting template of another scrap (scraps make the world go round!)

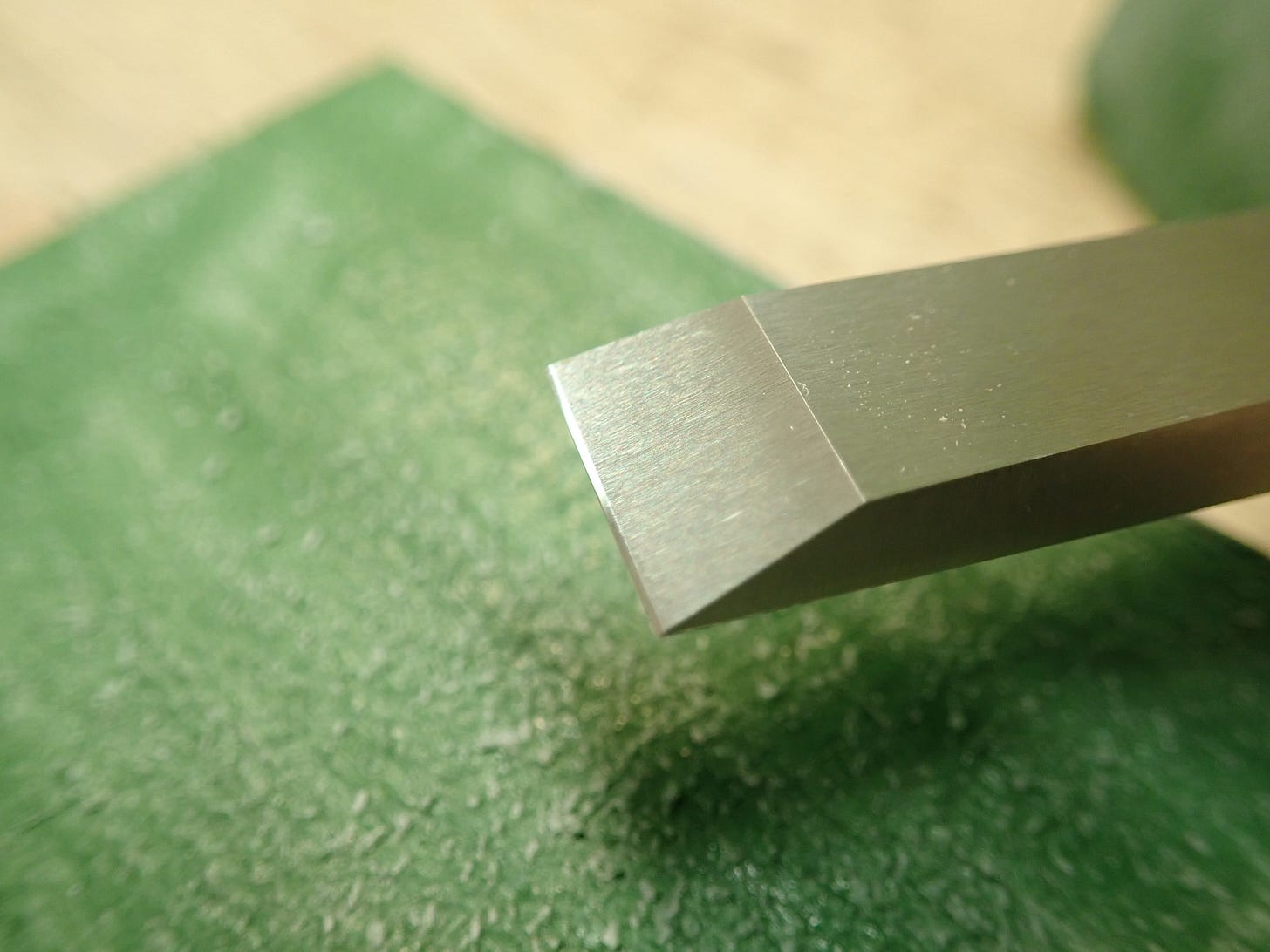

… and set about cutting out oversize leather bits with my Swann-Morton no 4.

Making stropping blocks entails glueing leather (hair-side down) onto wood. First I did a test using ‘white glue’ (PVAc) ...

… but I found it too easy to pull off — it separated cleanly; no real adhesion …

… so I tried with West System Epoxy.

That seemed to stick much better.

Now I was ready for glueing all the blocks at once.

Ready, steady, go!

After trimming the excess …

… I was able to do some initial testing.

The green Veritas honing compound is stated “to leave behind an average size scratch pattern of 0.5 microns”. I have two things to say about that statement:

1) The word ‘average’ leaves that sentence open to all sorts of misleading and perhaps dishonest interpretations. It should be the largest grit/particle size that defines the abrasive grading.

2) 0,5 microns … I hone down to 1 micron on my (industrially calibrated) sticky abrasives, and that equals roughly 10.000 grit on the P-scale. So the green stuff is … off even my autistic charts, apparently.

Whatever the material reality of the case might be, such very fine polishing compounds remove very little material, if at all. My old inspirator Brent Beach claimed that at these sub-micron levels, you’re mostly just pushing molecules around on the surface, and by a happy coincidence work-hardening the same.

All I can add is … ooooh! SHINY!

If readers have any links to worthwhile sources on stropping, please leave them in the comments!

I plan on doing further experiments soon — stay tuned!

***

https://scienceofsharp.com/2015/02/09/the-pasted-strop-part-1/

see: 'micro-convexivity'...

Thought you’d try hide glue just because, you know, seems somehow appropriate. 8-)