[ soundtrack : ‘Do I Ever Cross Your Mind’ - Allison Young & Josh Turner ]

***

This post is too long for email — open in browser for full length.

***

“Part 3! Will it never end?“ I hear you cry — in my mind’s eye … or ear?

It will end when it’s finished. Woodworking is all about patience and perseverance; it belongs to the slow and stubborn realm of realia, not the seemingly weightless, instant world of digitalia. It’s not like I’m forcing you or charging you money, is it? So … no sniveling — let’s plow on!

Last time we left off with splices glued and clamped.

When repairing windows it’s always the same: They rot from the bottom up (hint: rainwater + gravity), so it’s always the bottom rail that’s worst affected, then the lower, outer parts of the stiles. On these frames I had to replace the bottom rails …

… and put a splice in the lower, outer part of each stile.

With that done I had to plane the splicing-pieces down to dimension. I make the splices 5 - 6 mm oversize so as to have a couple of millimetres leeway on each side during the glue-up.

Usually, the old parts you’re trying to restore are both bent and warped, and you don’t want to reduce them too much in thickness, so you have to proceed cautiously, checking for straightness, square and dimension as you go. “Ginger carefulling!“ as Uncle Bumblefuck would say.

I use my old Baileys for this job; the No.6 quite coarsely set for removing millimetres, the No.3 finely set for adjusting dimensions and squareness.

With that done, the next task is to form the rebate for the glass and to shape the profile/counterprofile. The joinery on these glass-frames is ‘modern’ in the sense that it is cut on a moulding machine using a counterprofile cutter head (tool). If I had to guess I’d say that these windows were made in the interwar years in a ‘town-shop’, but they could also have been made after WWII. It really doesn’t matter — they’re rotten now.

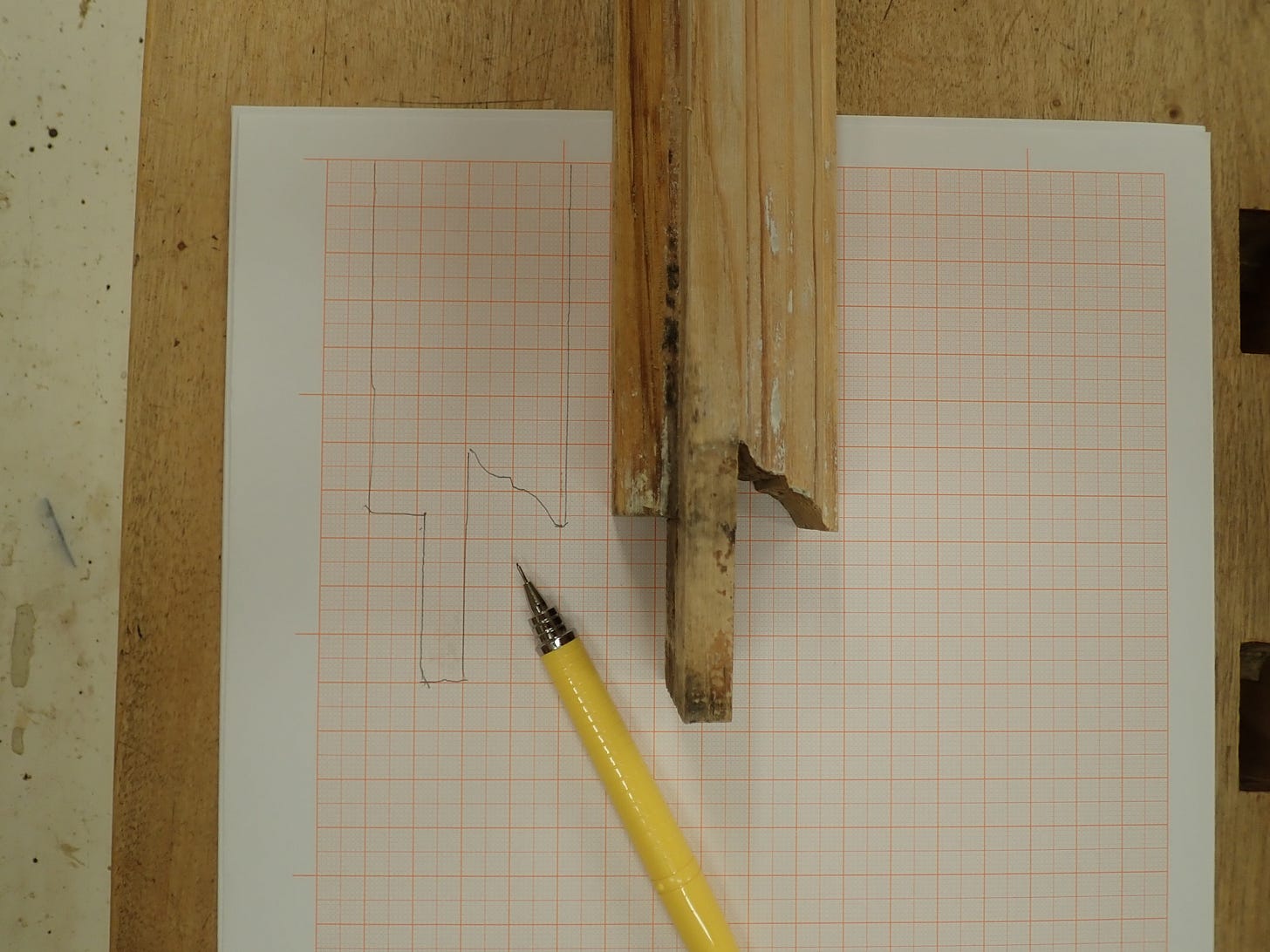

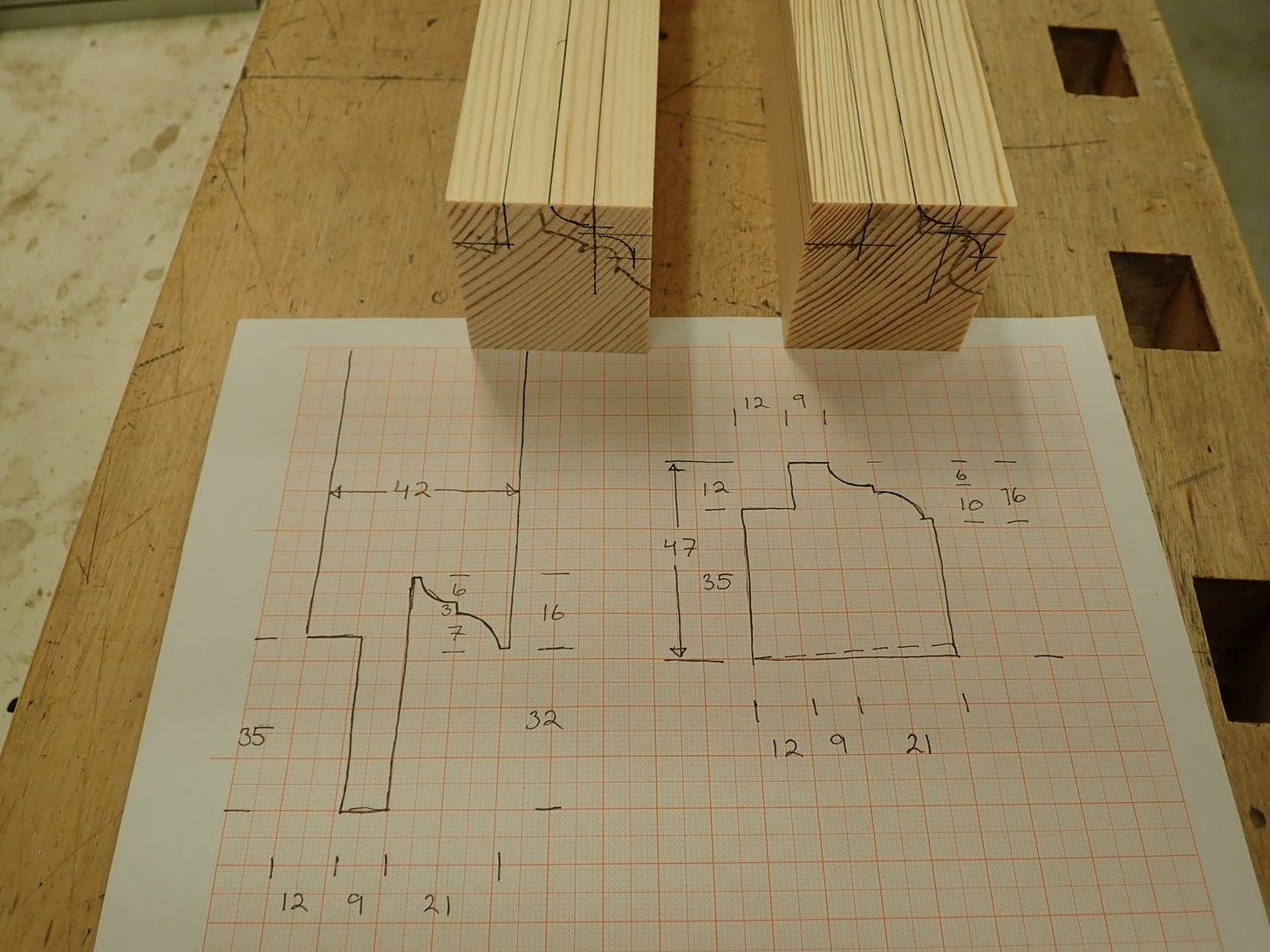

I don’t have that kind of cutterhead in my little shop, so I’m obliged to improvise. Don’t complicate things; put your best preserved specimen on a piece of paper and trace around it with your sharpest pencil!

Then measure it up as best you can using whatever tools you have at hand. You need to know ‘how many millimetres where’ — at least as a starting point.

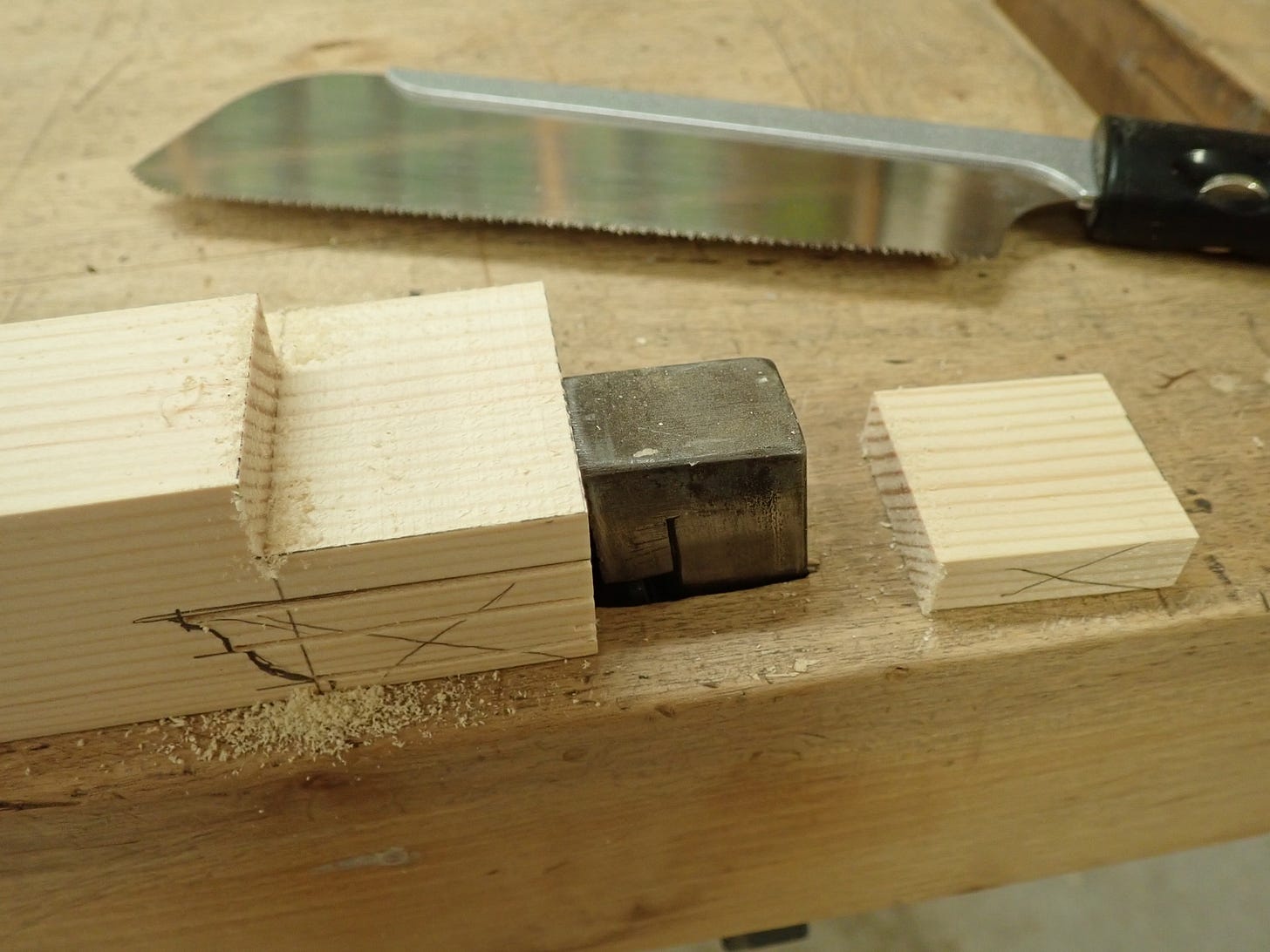

I tend to begin with the easy bit to boost my confidence; the glass-rebate. I rip it a tad undersize on the table saw …

… before adjusting it with a shoulder plane. All measurements are provisional on a job like this: parts have to fit each other — their nominal measurements are of secondary importance. You work by eye and feel more than by numbers. If it looks right, it probably is right. A ‘good eye’ is a most valuable trait for a woodworker — it’s not something you’re born with, it’s a skill you develop through experience … mostly bitter.

When shaping the ‘lengthwise profile’ I begin by making measured rebates to remove most of the wood, easing the work of my little table router that I use for making the round shapes.

I forgot to take any pictures of the routing process, so you’ll just have to imagine the excitement and derring-do involved. Anyhow, this is the result:

When all pieces are spliced and planed back to their original dimensions, make sure to mark them clearly so as to un-confuse yourself when glueing them back together. Never underestimate your own capacity for idiocy!

Next up is the joinery. Again; don’t over-complicate! Use your best-preserved piece to mark over the necessary shape with a sharpish pencil.

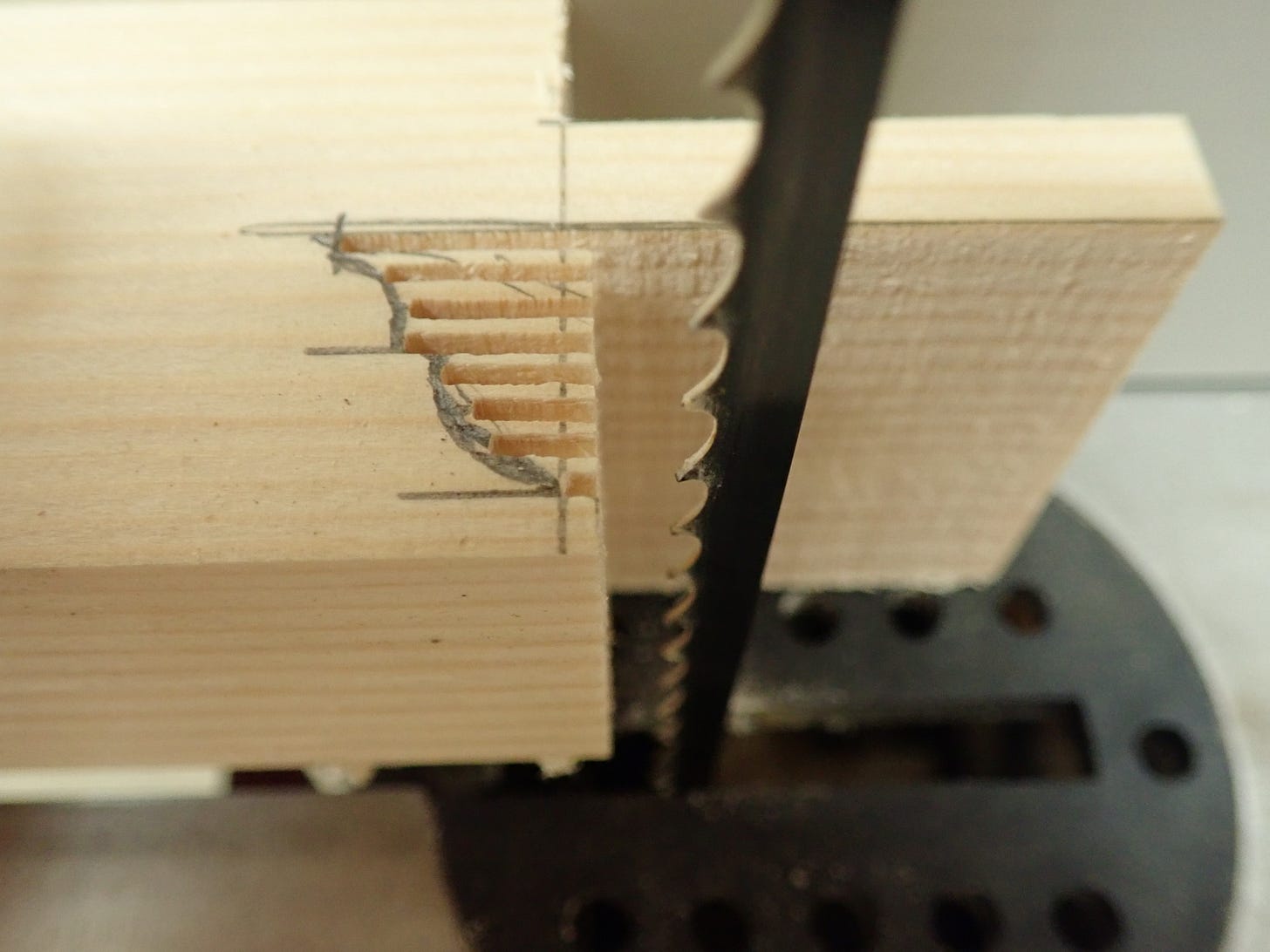

As mentioned, I am not able to mould/rout the missing profile onto the end of the rails, so I’ll have to hack it out somehow. I use the bandsaw …

… before losing some waste.

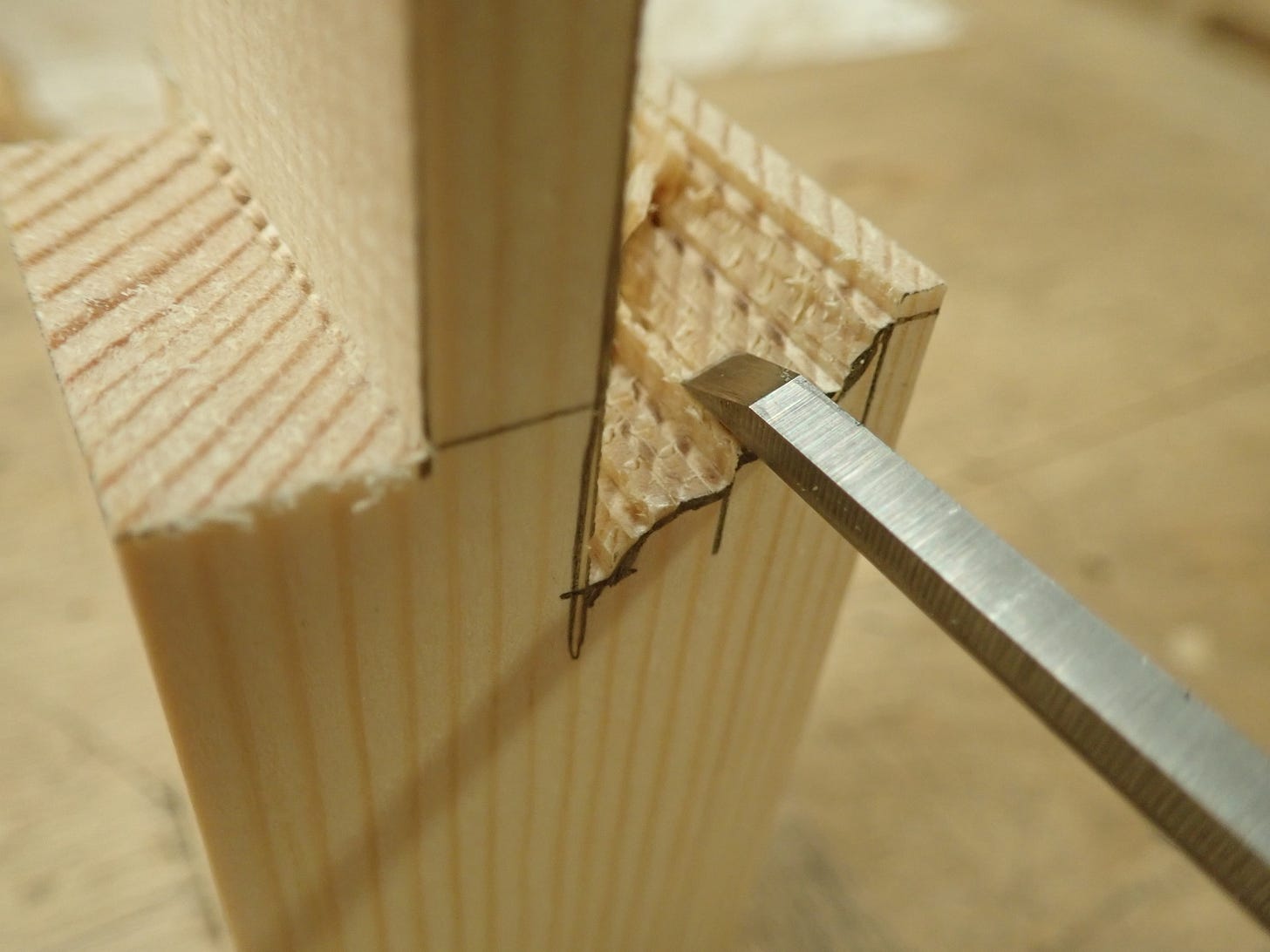

Then I weaken the remaining wood by incremental incisions …

… before paring out the rest of the profile using a narrow chisel and adjusting the shape with shaped files and rasps.

It doesn’t have to be a tight fit …

… because I’ll be using thickened, gap-filling epoxy for glueing (after applying two smearings of unthickened glue to saturate the thirsty, old wood).

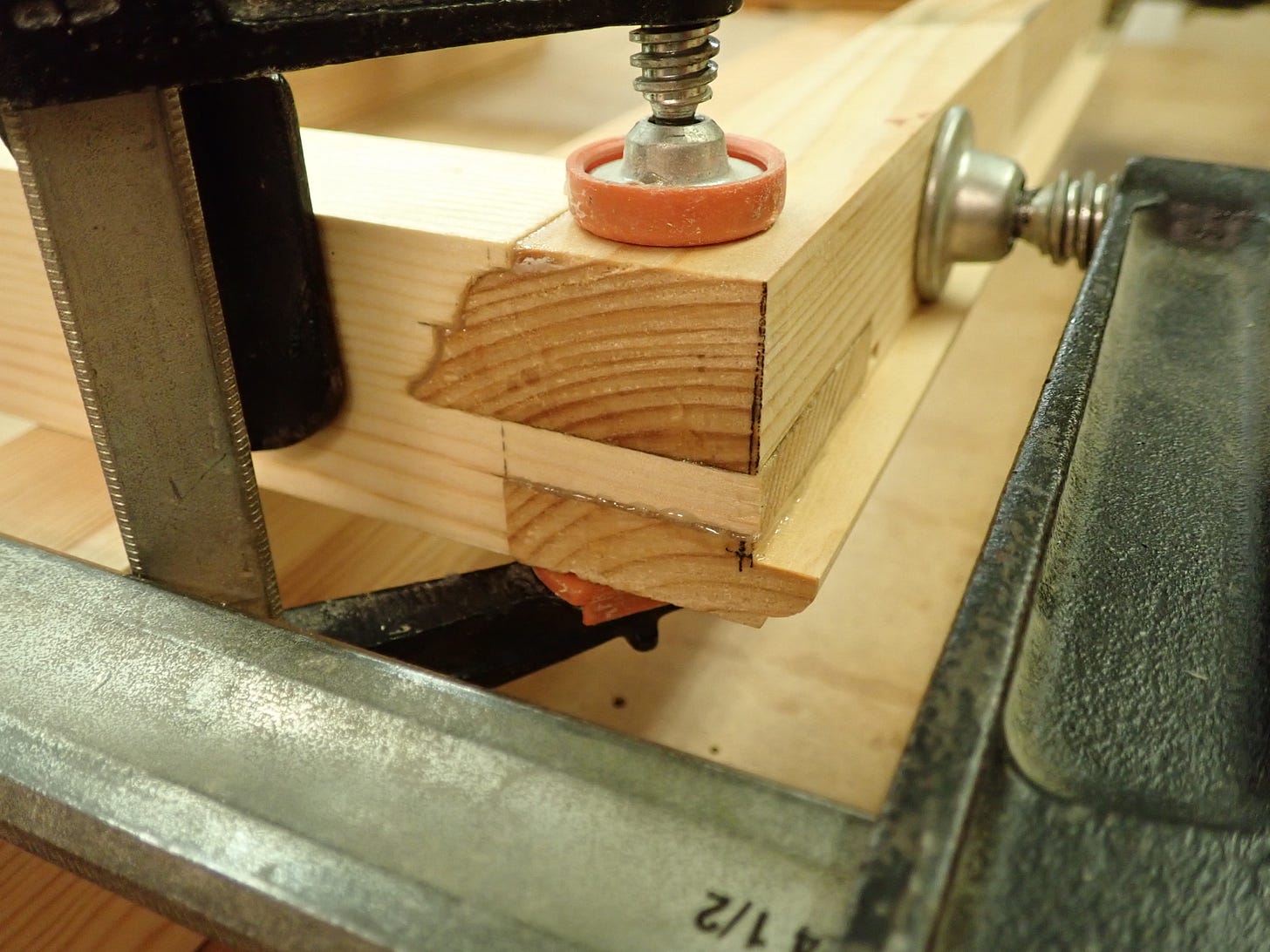

Clamp up, measure diagonals (remember: clamps more parallel to the longest diagonal to make square) and clean up un-cured glue with a small spatula and alcohol-soaked paper towels (wearing latex gloves).

I think we’ve all deserved a drink now. Skål!

***

The vicar is lucky to have you work on the windows. You've struck the perfect balance of contempt for the decision to "keep the good bits" and professionalism of delivering an excellent bit of work.