[ soundtrack : Hiromi Uehara - The Tom and Jerry Show ]

***

I can’t see myself not making things out of wood. If I don’t keel over by the bench they’ll probably have to pry the X-Acto knife out of my arthritic, dead hands (μολὼν λαβέ!) and throw the unfinished balsa-model of the de Havilland Mosquito in the skip ouside the old folks’ home. If so I’ll have finished as I began.

But before it comes to that I have other plans. I might have 20 years left at the bench, hopefully more. Regardless, my strength and stamina will wane; it already has. To compensate I’ve become lazier in the cleverest ways :-) I remember when I was a young woodworker (strong as a bull — full of spunk and bravado), I used to hang out in Harold Skjøldt’s ‘Old Boy’s Workshop’.

He was a master furniture maker and luthier, and had taken a shine to me. (“Du er gutten som vil og kan!“ = “You’re the boy who will and can!“) He must have been in his seventies then and spent most of his time in the ‘office’ drinking coffee and quarreling with his mate Herbert — an old trade union rep. whom he gleefully patronised for not being a craftsman. My point here is that I remember seeing him work quite effortlessly. When handling materials he would slide, tilt, flip, rotate, shift and balance a plank through the usual processes until it was reduced to easily manageable pieces. Where I would unthinkingly rely on my young muscles he would conserve his limited strength and rather rely on practised ‘laziness’. It was an eye-opener for a young woodworker, and the reason why I keep my work surfaces smooth and clean, edges rounded over; so I can shift a piece by sliding or rotating it without it getting scuffed up. Work smarter, not harder!

There will come a time when I’m no longer able to carry 5 metre 2” x 10” pine planks on my shoulder. That’s why I’ve started looking for an apprentice. She should be a strapping lass of keen intelligence; dexterous, polite, from a good family, with a penchant for classical music, without social ambitions and indifferent to the possibilty of accidentally amputated fingers or even monetary remuneration. Shouldn’t be too difficult; a notice at the local psychiatric hospital should do the trick.

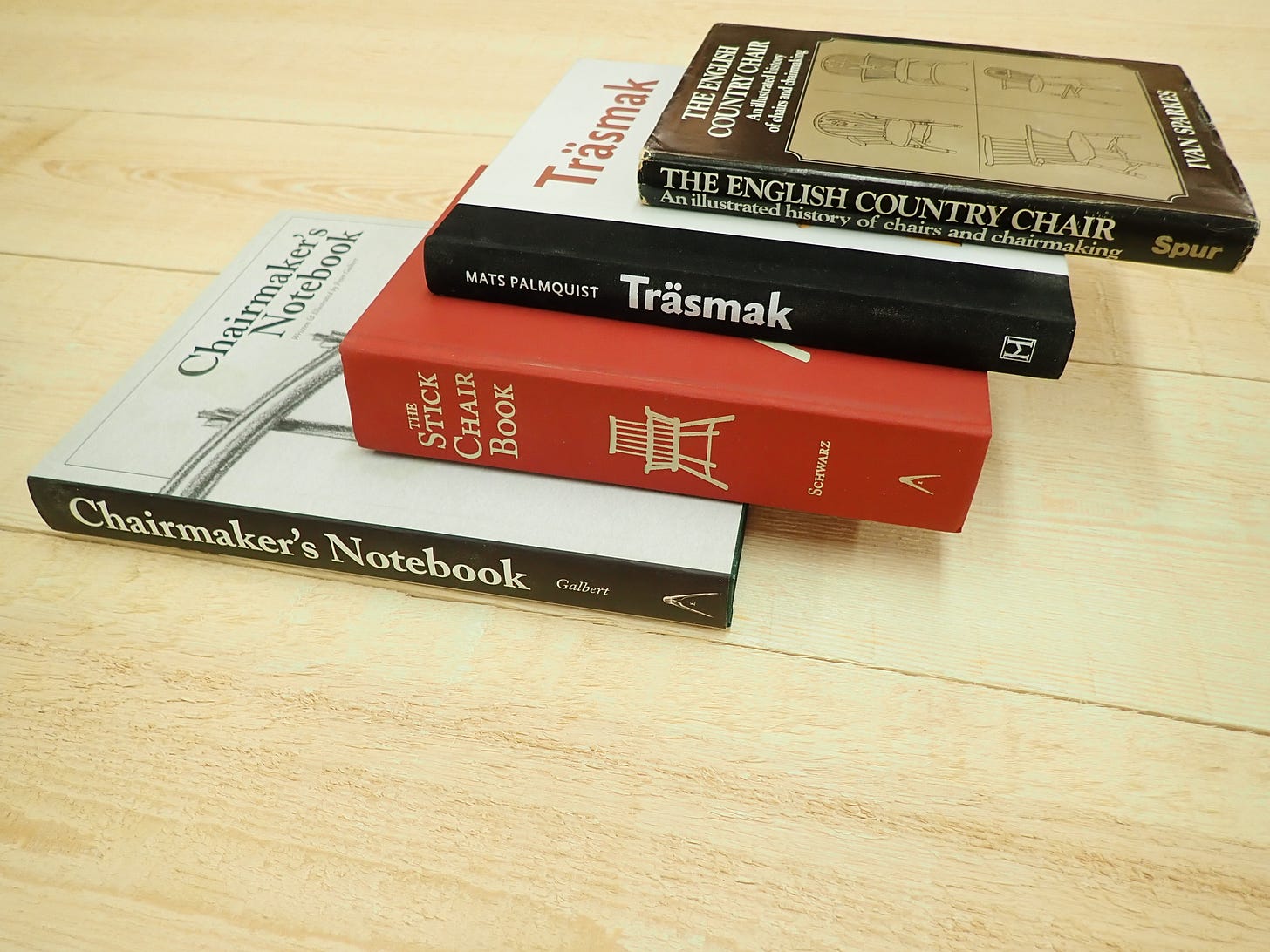

But seriously. When (if!) I grow old I will build chairs. Stick chairs. That’s my plan. Heaviest part of them is the seat; rest of it is just thin sticks the length of your forearm or so. A chair is more geometry than actual wood — light work suitable for old folks. And this is why I’ve started buying chairmaking tools and books on the sly.

I’ve even bought the smallest, cheapest lathe so I can teach myself turning …

… in case I feel like making something Windsor-like, some table legs, or perhaps bannisters. It’s very good to be able to easily make shapes in wood.

But to get to the point of this post: I’ve bought an inshave. An inshave, sometimes called a ‘scorp’ is used to slightly hollow out (‘saddle’) chair seats so your posterior might rest comfortably.

Two and a half years ago, as I was reading the Lost Art Press blog, I came across this post. I promptly signed up for the waiting list and goddamn! two years later George Sawyer sent me a mail asking if I would still be interested? Hell, yeah! The shape of the inshave was developed by Sawyer senior, is today sold by Sawyer Junior and is made by independent blacksmith Lucian Avery. Today I picked it up at the post office and tried it out.

It arrived well packaged with a nice, functional edge-protector.

It’s a beauty!

The cutting edge is better honed than you have the right to expect from a batch production run like this (this is not an ‘industrial product’). If you’re able to reproduce this initial level of sharpness, your honing skills are good. I’m not saying you couldn’t do better, but remember: You’re honing only one … try doing 300 and tell me how you’re getting on with it!

I had to try it out at once and found an old stump of Scandi pine:

It just wants to eat wood like it was cornflakes! Clean, effortless, crisp cutting.

It’s so pleasurable carving away at wood like this :-) The way the sharp edge cuts cleanly into the wood … and the crisp sound makes me want to take up woodcarving. Try this: Hone your best chisel to perfection and stick a nice piece of wood in your bench, vertical like. Now, have a go at the end grain of the wood with your lethal friend … cut a chamfer … make it wider … go downgrain … flip the chisel bevel down and cut out a hollow … hear that sweet sound of wood fibres being severed? Doesn’t that make you want to carve something? Anything?? That’s the madness I’m talking about. You’ve either tasted it or you’re still blissfully unaware.

Next, I’m in the market for a travisher or two …

***

“A chair is more geometry than actual wood” - I love this thought. Really gets to the heart of the matter. Glad you’re pleased with your inshave. I bought a cheap one off eBay and of course it turned out to be a cigar butt of a tool. You’ve convinced me to step up and get something of quality.