[ soundtrack : ‘Little Birdie’ - Margo MacSweeney ]

***

This post is too long for email — open in browser for full length.

***

A scrub isn’t a plane I need that often, but when I do it’s just what the doctor ordered. Traditionally, the scrub plane is what the Continental Europeans would use to roughly flatten lumber where their Anglo-Saxon brothers would use a jack plane. I’m Nordic and have no compunction about using either as might suit me best. Besides, I hardly need an excuse to buy a new plane :-) This is the latest haul from my man in Berlin.

Most of the time, working in my shop, I use machines to turn lumber into flat, square and measured dimensions, but sometimes this is not possible; If I’m splicing big, rotten parts that are impossible to manhandle onto the machines, or if I’m out moonlighting as a timber-framer and have to dress a beam. Our Master timber-man would wield his hewing axe and waste it in a minute, but my wrist is barely strong enough to swing a Boy Scout’s hatchet, so I resort to sharp and hungry hand planes instead.

I also have an electric handplane that’s capable of hogging off considerable amounts of material, and I do sometimes use it, but I do not like it. I pride myself on being a pragmatic sort, but I just cannot be doing with it, except when I have to plane mucky stuff that I wouldn’t touch with any of my handplanes; then I’m happy to dig out the handheld electric planer with its replaceable cutters.

My newest scrub plane is made by ECE and has a body of red beech and a sole of hardwearing hornbeam. It’s an industrial product (not hand crafted), but precisely made and attractively priced.

I find wooden planes of this kind very pleasant to work with; their light weight, low friction and excellent ergonomics make them delightful companions, and the easy way they fit in your hands is a joy. Unlike the rear tote / handle on our steel planes that we’re accustomed to hold with a gripping fist, these planes invite a more open ‘fingers forward’ hold. It’s relaxing, yet firm enough. It’s better! The horn is also comfortable to hold.

I have other ‘roughing out planes’ too: a vintage Norwegian scrub with a Swedish iron that I had to modify by rounding its sole in order to get a job done (I’m not squeamish about modifying tools — they are tools, not collector’s items), a Lie-Nielsen scrub and a Franken-Stanley jack plane with a selection of variously cambered irons.

Usually, the lumber in need of flattening is just cupped 2 or 3 millimetres …

… and then a well-cambered jack will do the job and leave a less scalloped surface to go on with. The more aggressive scrub plane is best suited for when you need to remove more than a trivial amount of wood (that you can’t hew or saw); I tend to use it more as a thicknesser than a flattener.

Let’s set it up and see how it behaves!

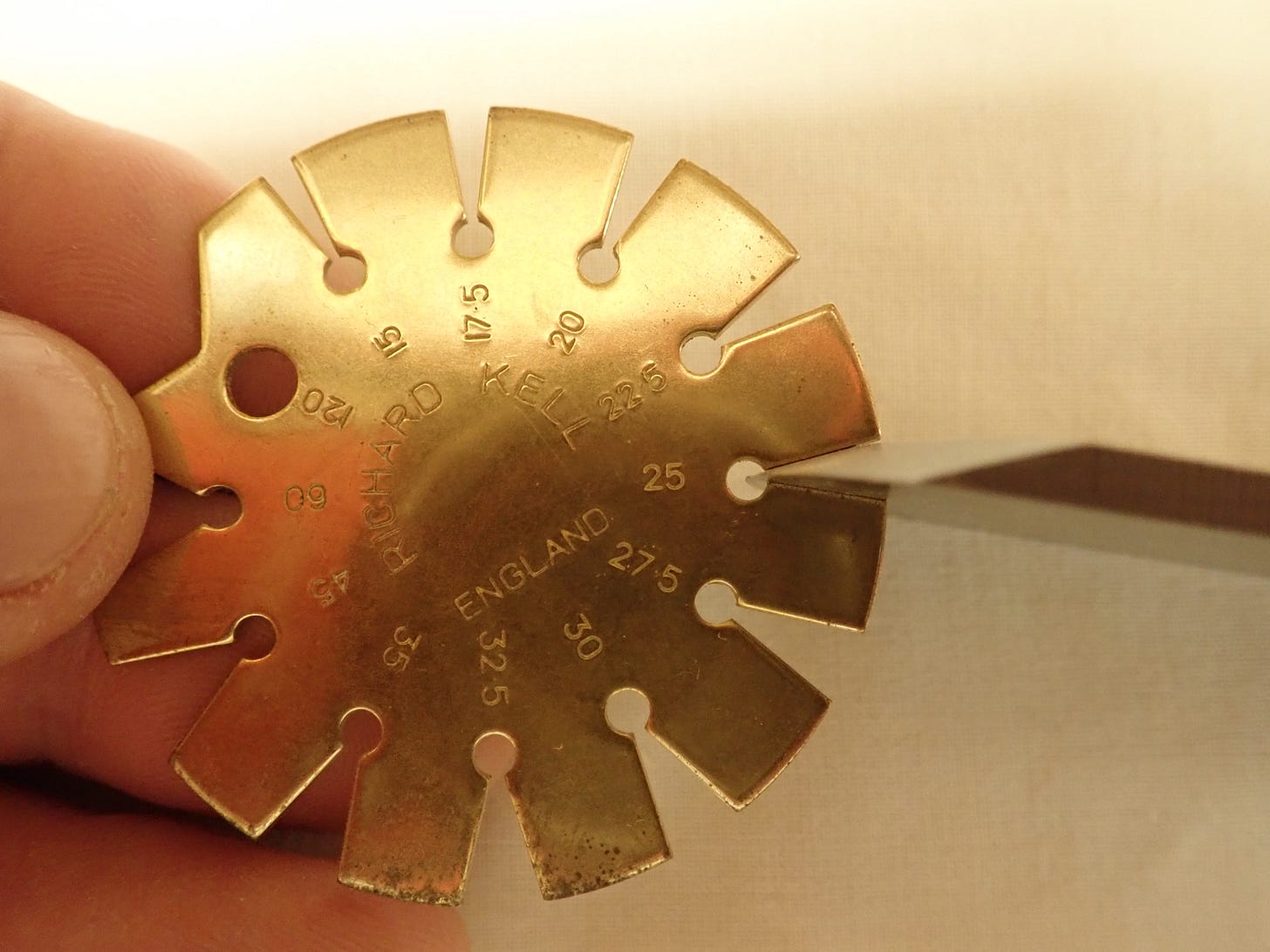

The iron came with a primary bevel of 25º.

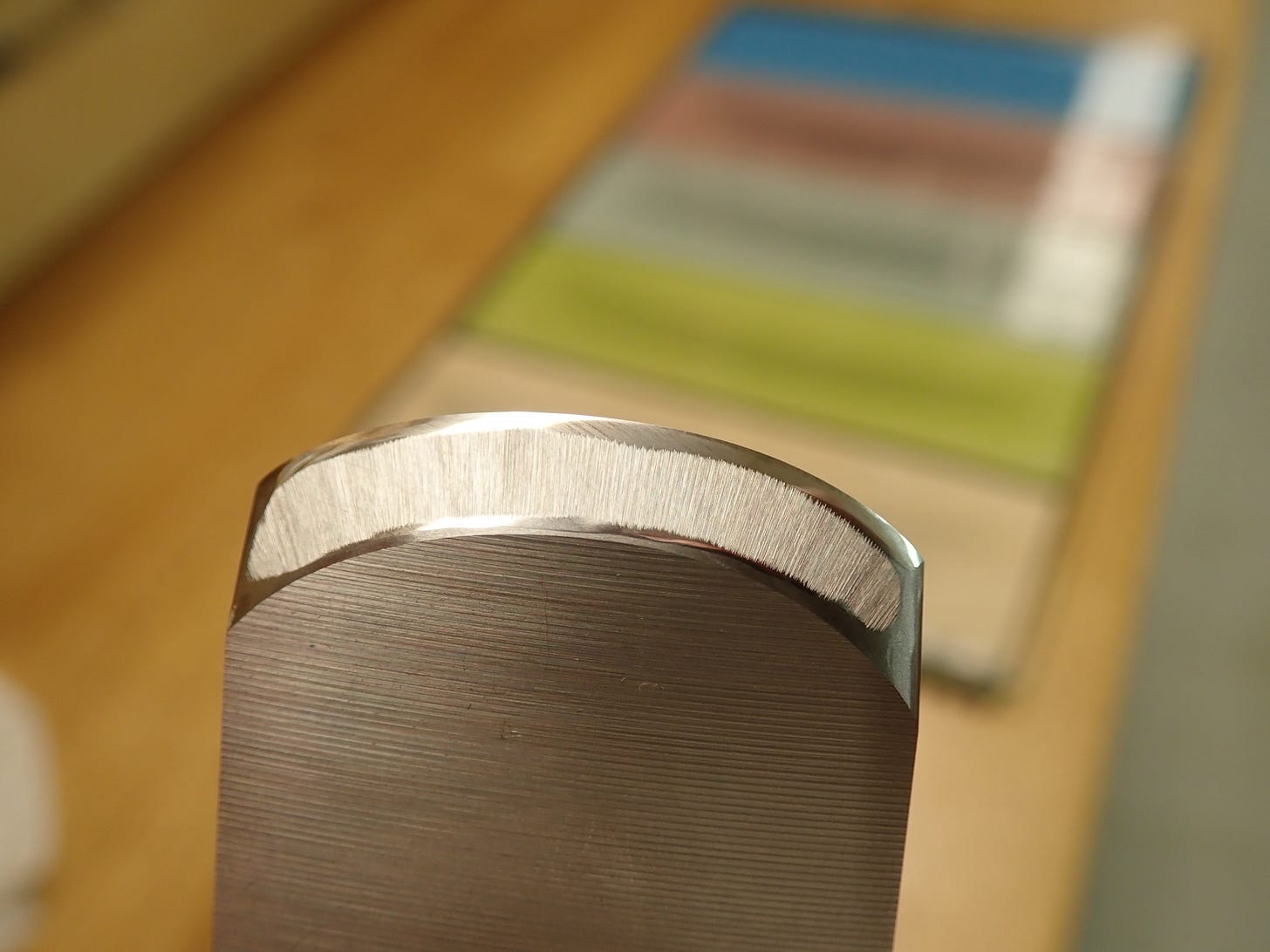

Most scrub planes come with irons ground to a circular radius. I prefer a flattened, more elliptical shape, so the first thing I did when setting up this plane was to regrind (flatten) the camber a bit.

Use light pressure, a freshly dressed wheel and dip often to avert overheating!

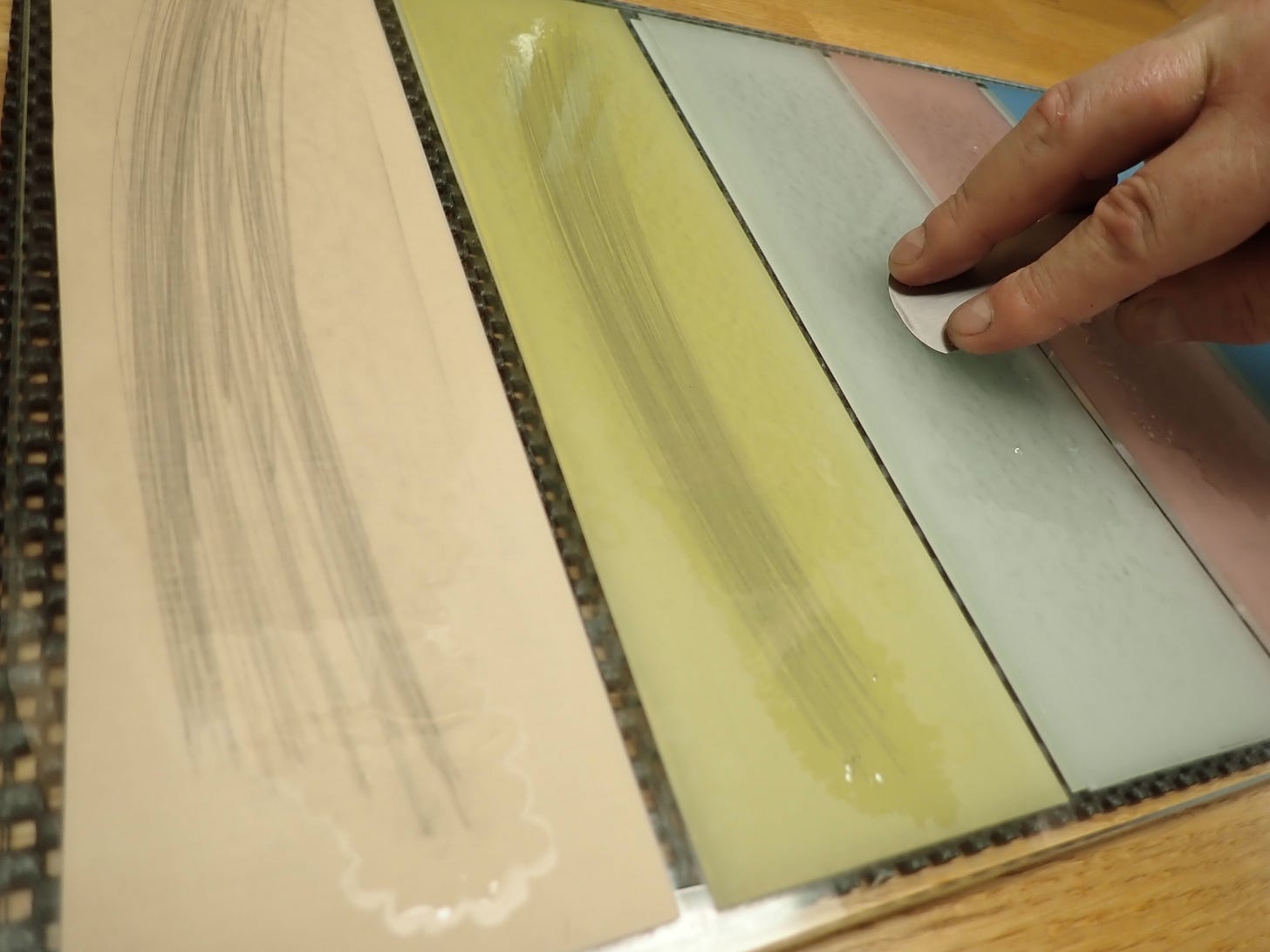

The exact shape of the camber is not critical; it’s not a moulding plane, so I just go by eye. Same goes for honing: a hogging plane like this does not have to be wicked sharp — although it doesn’t hurt! — so I do it freehand by ‘side-swiping’.

A soft leather strop would also be suitable for honing irons of this shape.

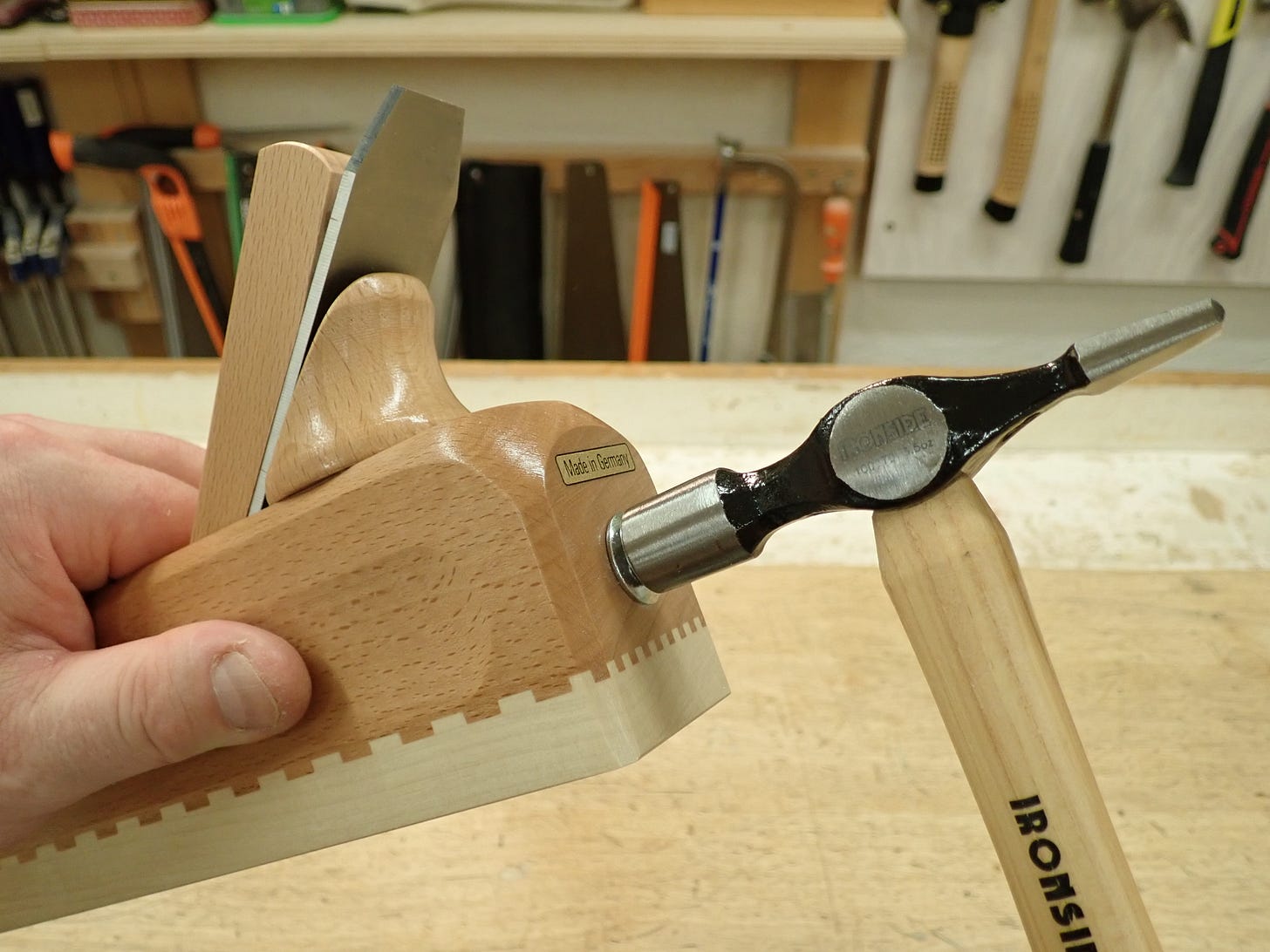

In case you’re unfamiliar with wooden planes and how to set and adjust them, here’s how I do it: Place the plane on a flat surface and slip the iron down its throat until the cutting edge rests on the surface. Hold it in place with a finger or two while your other hand inserts the wedge and gives it a little push to seat it.

Next, lift the plane and give the wedge a light tap with your daintiest hammer.

To advance the iron, just tap the protruding, upper end of it. You can also tap it sideways. When satisfied with the cutting iron’s position, give the wedge another light tap or two to firm it up.

If you want to retract the iron, or loosen it completely, give the plane some sharp knocks on the steel button on its rump; the shockwave will loosen it up.

A common mistake is to overtighten the wedge. Don’t! Give it a tap and try to pull it out again with your fingers. This will give you a feel for how well it’s stuck in there.

So, how did it perform?

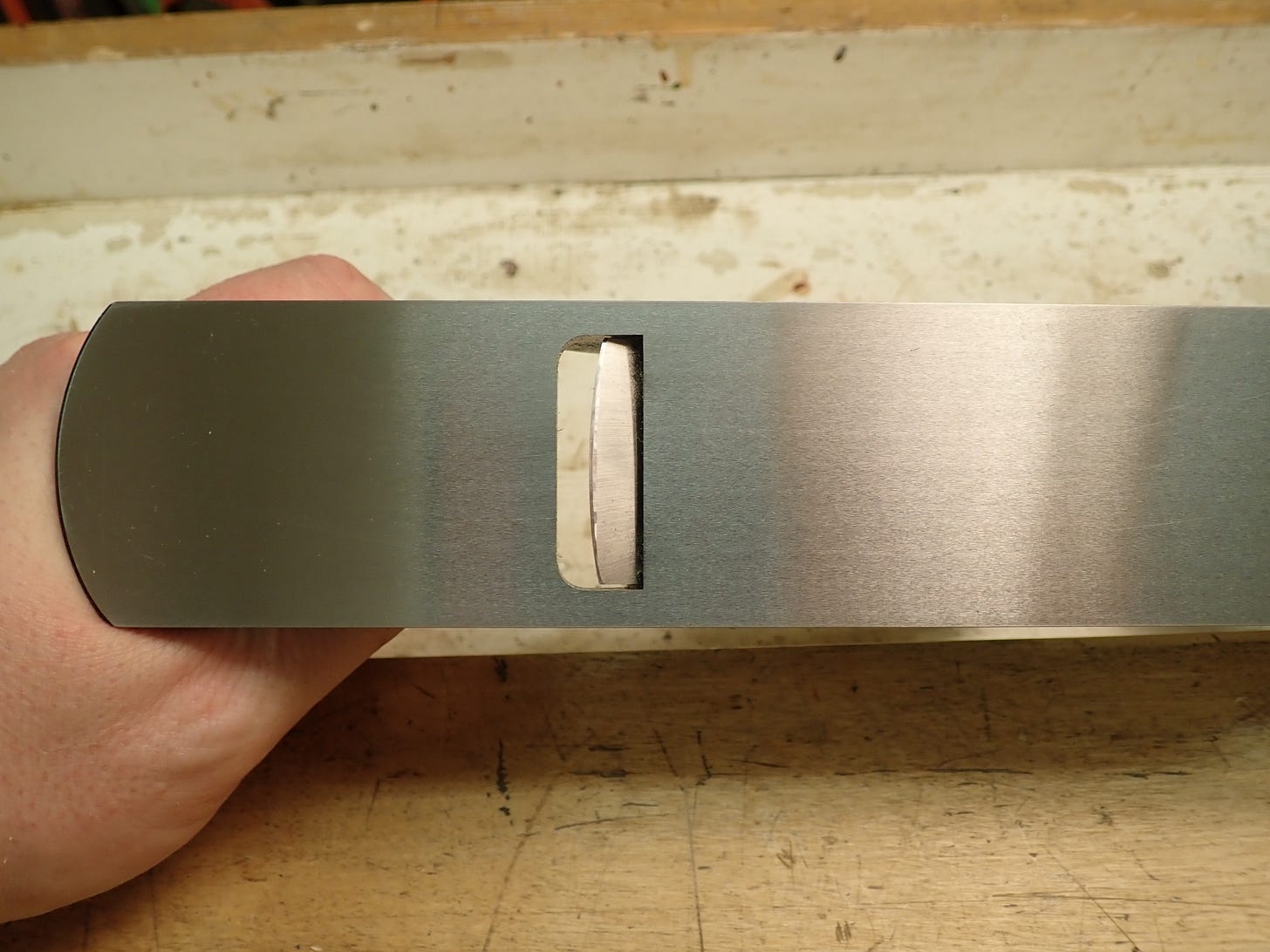

Well enough, but it felt a bit choked; it could have cleared its throat with greater ease. Let me explain: I’d noticed that its mouth was fairly tight, more like what you’d expect to find on a normal bench plane …

… which is unnecessary on a scrub plane as we’re not concerned about preventing tearout, but in moving amounts of wood up and through the plane, and pursed lips do nothing to aid that flow. If you compare with the gaping maw on the Lie-Nielsen steel scrub you’ll see what I’m talking about:

Scrubs and end-grain-planing block planes do not benefit from finely set mouths. Thankfully, with a wooden plane it’s easy enough to remedy; I simply extended the iron and used its shape to mark out a larger mouth.

Then it was quick work to enlarge the opening with a cabinet maker’s rasp.

Much better!

It’s one thing to cut the wood, but the waste must also be moved out of the way. This holds for all manner of woodworking tools.

A scrub plane should be used diagonally to give cleaner cuts and to reduce spelching on the outfeed side. First one way, then the other; the crosshatched pattern has a flattening effect in itself. You can also use the scrub along the grain — especially if you retract the blade a bit — so long as you can live with the atrocious tear-out.

A scrub plane is good for removing a lot of material but leaves a scalloped, rough surface in need of further refining with a jack, a try plane and a smoother (if you need to go all the way — often, you don’t).

Try a wooden plane! They are friendly and fun, but please don’t buy a warped and cracked ‘antique for restoration’ unless you really know what you’re about. Why not buy a cheap, non-descript wooden plane from some no-name producer so that the cost of failiure is negligible? Then you can play around with it and learn a lot about what makes planes work well. I dare you!

***

Nothing like a good scrubbin!

I start with a scrub, go to the jack and end with the smoothing plane. The same 3 piece combo Muhammad Ali used to stop Joe Frasier in the 14th round. Exact same