[ soundtrack : Nick Cave & The Bad Seeds - Stagger Lee ]

***

There are several ways of making tenons. How you do it depends on which tools you have at hand, which quality the job requires and the number of tenons you have to make.

The obvious starting point is to cut them using hand tools. I won’t go into that here; on YouTube you’ll find any number of expansive personalities more than happy to show you how it’s done. Instead, I thought I’d quickly show you a way to cut tenons on the bandsaw.

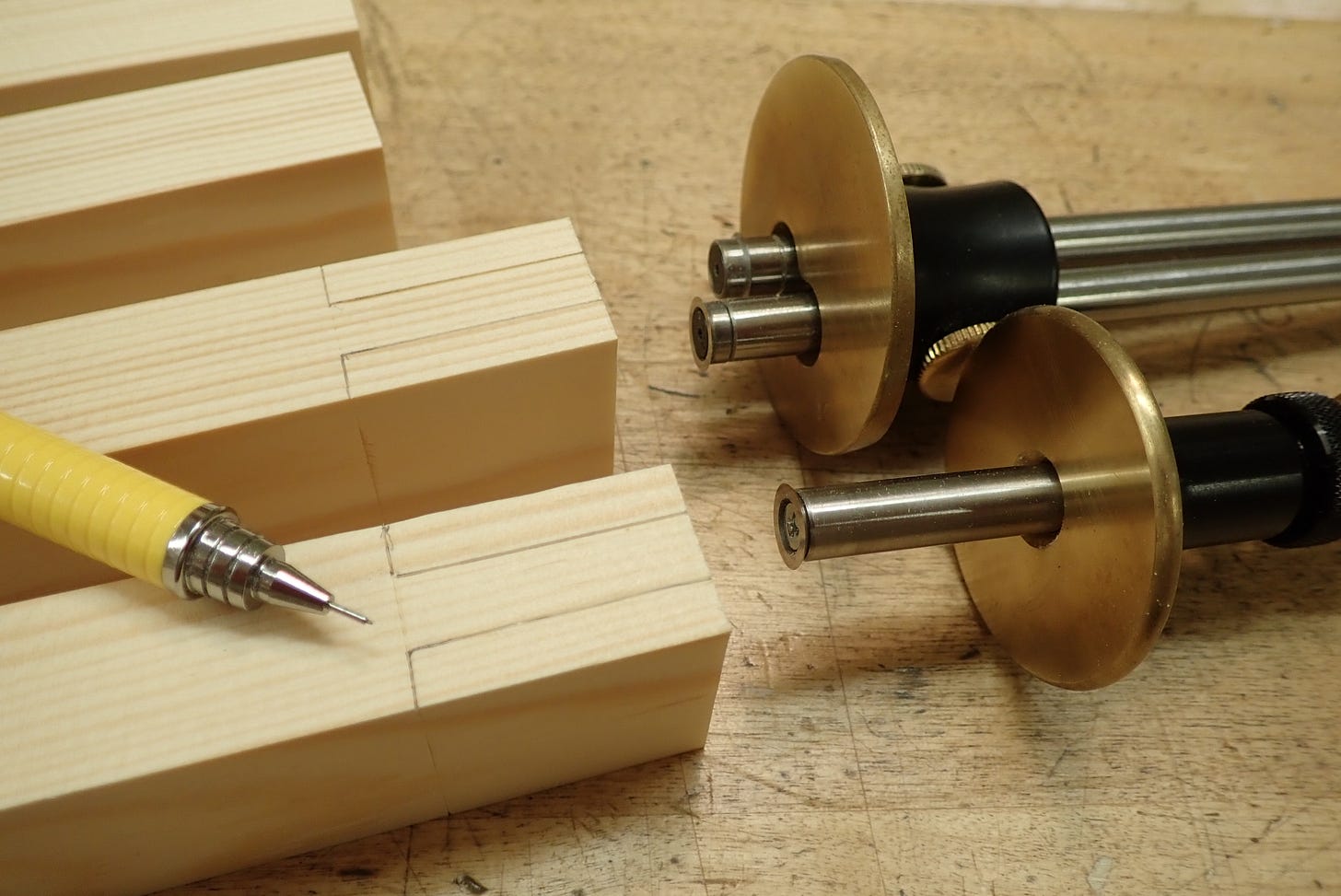

When you cut tenons by hand you need to mark / lay out every tenon on every piece so that you know where to cut. No big deal if you’re making 1 frame with 4 tenons. Much bigger deal if you’re making 12 frames with 48 tenons, or 48 frames with ...

With the bandsaw-method you only need to lay out two or three ends on some test-pieces.

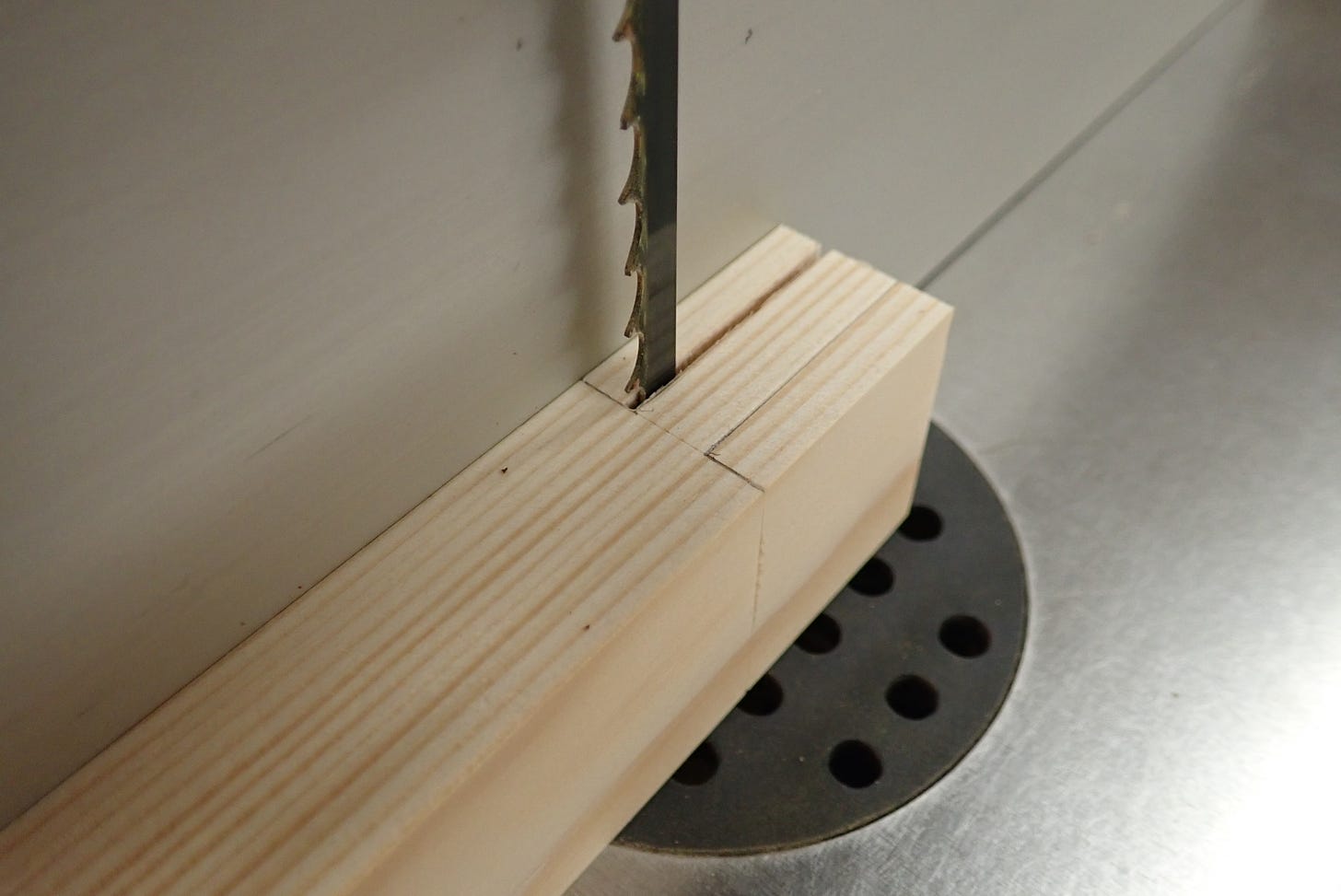

Start by setting the fence on the bandsaw and cutting down to the shoulder:

Hold the work-piece still while you turn off the saw. Then clamp in place a ‘stopper-block’.

Before we continue; a word of caution regarding using clamps on machinery: Machines vibrate. Some clamps will be loosened by these vibrations. This can cause inaccuracies if it happens slowly, without you noticing — ‘slippage’ — or it can cause more dramatic results if your machine set-up is so disposed; try to avoid that! The only way of knowing which clamps will hold fast on machines is by experience. I keep a selection of tried and tested ‘machine-safe’ clamps in my machine shop for this reason.

Safety when woodworking is dependent on your own understanding, sound judgement and prudent foresight. Safety is not so much about learning ‘rules’ as understanding the process you are engaged in and which forces are at play. Woodworking machines are fearsome, but being afraid will only weaken your resolve and make matters worse. Confidence comes with experience, and let’s be honest; isn’t a modicum of calculated danger deliciously exhilarating on a rainy Tuesday afternoon?

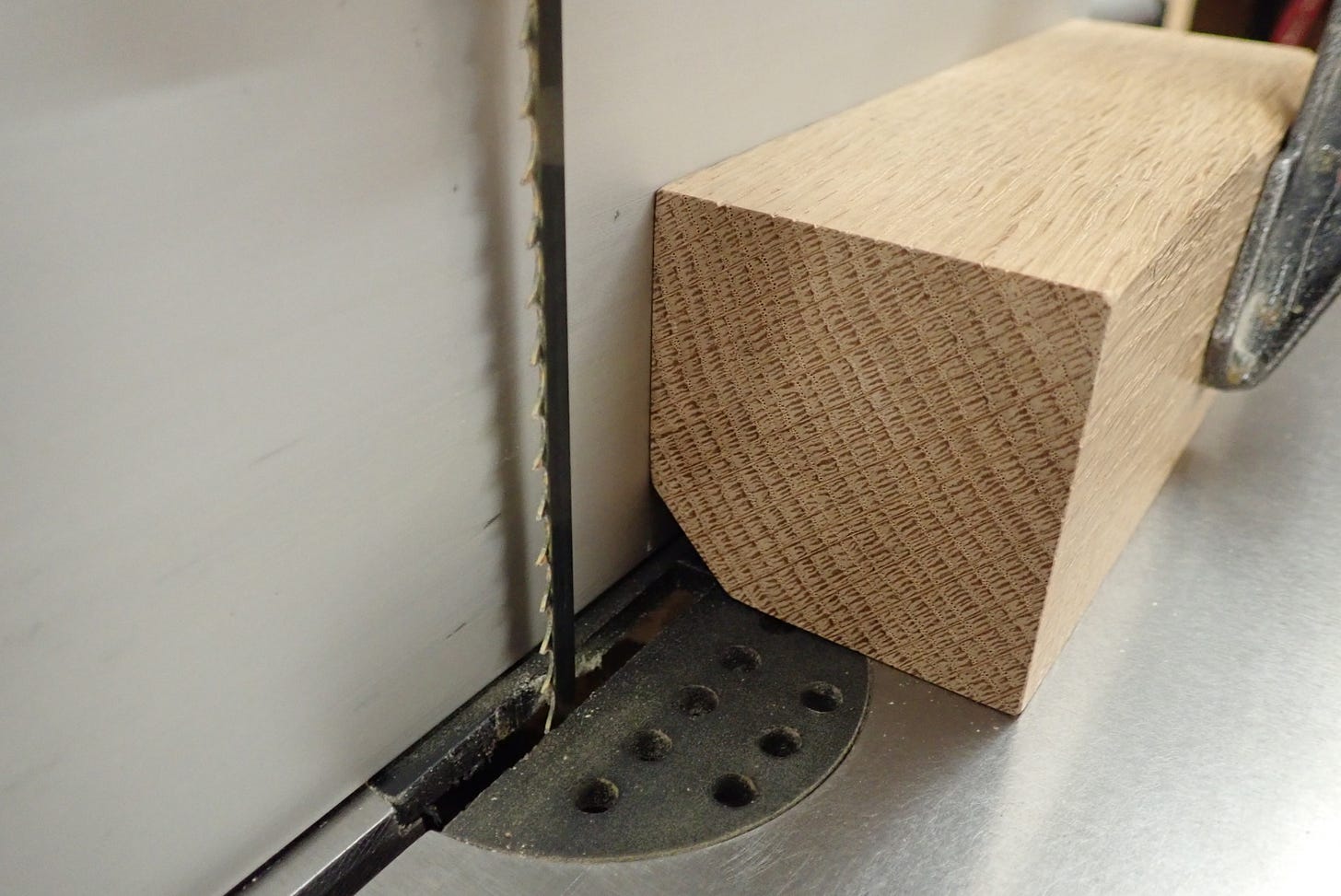

Back to our clamped-in-place stopper-block! It is helpful if it has a generous chamfer running along the edge that faces the corner between the fence and the machine table. This tunnel provides an escape route for the sawdust that otherwise would enjoy packing itself between the stopper and the work-piece. Blow it away!

This simple set-up, where the fence guides your cut ‘sideways’ and the stopper limits your depth, allows you to repeat the same incision without laying out any lines. You simply flip the work-piece around to do the other cheek … I think Jesus mentioned this in his Sermon on the Mount.

… and then you flip it head-over-heels to do the other end of the stick.

I trust it goes without saying that you can cut the corresponding open mortises / slots using the same technique — just remember to cut on the other side of the marking line, lest you end up two saw-kerfs slack.

The next step is cutting the shoulders of the tenon. I tend to use my mitre saw for this. It looks like this most days of the week:

I keep sacrificial scraps clamped to it to reduce tear-out (spelching) on the back and underside. To cut the shoulders I clamp in place another stopper-block, well … in this case, more of a stopper-strip (?) to set the distance …

… before I engage and adjust the saw’s depth stop:

It is no coincidence that the ‘stopper-strip’ is lower than the upper surface of the tenon. Being so, it does not hinder the newly cut-off ‘cheek-piece’ from moving away from the sawblade:

If the stopper-block were thicker (higher) it would trap the little cheek-piece between itself and the viciously spinning saw-teeth — a little ‘explosion’ just waiting to happen! It would be a miniature case of kick-back: the bad thing that happens when the longer diagonal suddenly decides to assert its dominance over the shorter straight length by wedging itself between the limiter and the spinny thing :-)

The bandsaw yields a somewhat rough-cut surface (and Old Mother Hubbard has a rough-cut punt, not a punt cut rough, but a rough-cut punt! What?)

Horses for courses and faith in the gap-filling glue, eh?

***

This format of learning about your processes is magnificent.

You've ended on the perfect cliff hanger as well - getting down to the line. The bit where the heart starts beating faster...

Thanks for sharing this. I enjoy reading about these precise, well-thought-through processes.